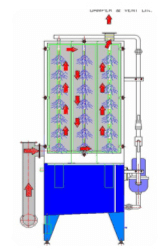

Chamber Machine

Smoke Chicken House Chamber

- Auto Controls Drying / Smoking / Cooking Process and controls individual process as needed.

- Basic standards are 2-trolley / 4-trolley. Double-door 3~4-trolley types can be configured according to installation place.

- Adjust proper smoke color and flavor according to each product. COLD SMOKING can be performed if a Freezer is applied.

- Designed for multi-functions and high-efficiency/energy saving type and the product has a deep smoke flavor and taste.

- It provides uniform smoke color and gloss and smoke flavor in optimum dry status.

Configuration

CHAMBER

STEAM GENERATOR

WET SCURUBBER

TROLLEY

CIRCULATION & EXHAUST FAN

CONTROL BOX

Ham & Sausage, Chicken, Duck Cold Smoking

Auto Rail & Door Intensive System

Automatic Control Steam Generator C.I.P System

Automatic Smoking system

Smoke products made by the smoking machine of HYUPJIN in Multi-functional/high efficiency (ENERGY SAVE) style has delicious and deep taste and flavor. Wet smoke flavor given in optimum dry status enables even coloring of the products in the Chamber.

- Basic smoke product: Ham/Sausage/chicken smoke.

- Dry House: Meat jerky / fried fish drying

- Freezer (OPTIONAL): low temperature marine products smoke

Specification

| MODEL | DIMENSION | ELEC | AIR | WATER | STEAM |

|---|---|---|---|---|---|

| HSH1T | 1600W*1500L*4100H | 5.5Kw | 15A | 20A | 20A/75kg |

| HSH2T | 1600W*2500L*4100H | 9Kw | 15A | 25A | 25A/150kg |

| HSH3T | 1600W*3800L*4100H | 13Kw | 15A | 25A | 32A/225kg |

| HSH4T | 1600W*5100L*4600H | 16.5Kw | 15A | 25A | 40A/300kg |

Capacity

| TITLE | 1TROLLEY | 2TROLLEY | 3TROLLEY | 4TROLLEY |

|---|---|---|---|---|

| HAM(Kg) | 200 | 400 | 600 | 800 |

| VIENNER | 100 | 200 | 300 | 400 |

| DUCK(EA) | 160 | 320 | 480 | 640 |

| CHICKEN | 150 | 300 | 450 | 600 |

Automatic Smoking system

Touchscreen type Control Panels of Hyupjin Machinery can be easily understood and operated by workers to ensure high operability. Basically, the panel displays current chamber temperature, progressing temperature, humidity and all work processes in the screen for easy checking by workers.

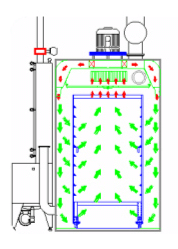

WET SCRUBBER

CIRCULATION

Automatic Smoking system

Features (comparison) of dry type and wet type

| Div. | Dry Generator | Wet Generator |

|---|---|---|

| Smoking color fixing principle | Completely heat (dry) product skin to form skin layer, and spray on the generated skin layer with dry smoke to generate smoking color. Hence, There is big difference of discoloration degree of smoking color between cooling washing (shower) and storage in the cooling room according to skin layer status. | Form thin skin layer. high-temperature and wet smoking machine will open porous skin tissue during smoking and smoking color will be generated by penetration into product skin in the smoking machine by temperature difference between product temperature and smoking machine. Hence, discoloration difference is very low comparing to that of the existing method during storage in the cooling washing and chill room. Added to that, product can be manufactured with stable smoking color. |

| Sawdust transfer method | Supply imbalance due to simple free fall method | transfer of fixed quantity using the screw |

| Smoking generation temperature range | Heating with 400 ~ 700℃ (surface temperature of the heater). Temperature adjustment is impossible. | Continuous selection of proper temperature is possible within the 250 - 350℃ range, generation of uniform smoking |

| Smoking adjustment time | Time adjustment is possible but imbalance supply quantity of sawdust. Hence, adjustment of smoking degree is impossible. | Regular sawdust supply is possible. smoking amount can be adjusted by an operator |

| Product error rate | Over generation of smoke amount at the time of initial ignition | None (However, it can occur if cleaning status is not good.) |

| Auto fire extinguishment function | none | Auto fire extinguishment (vacuum) after operation |

| Feature | - | The main purpose of the steam supplied to wet generator is to supply high-quality smoking scent. It also filter noxious gases generated during combustion of CHIP and exhaust them out of the generator. (Drain device in the generator chamber.) |